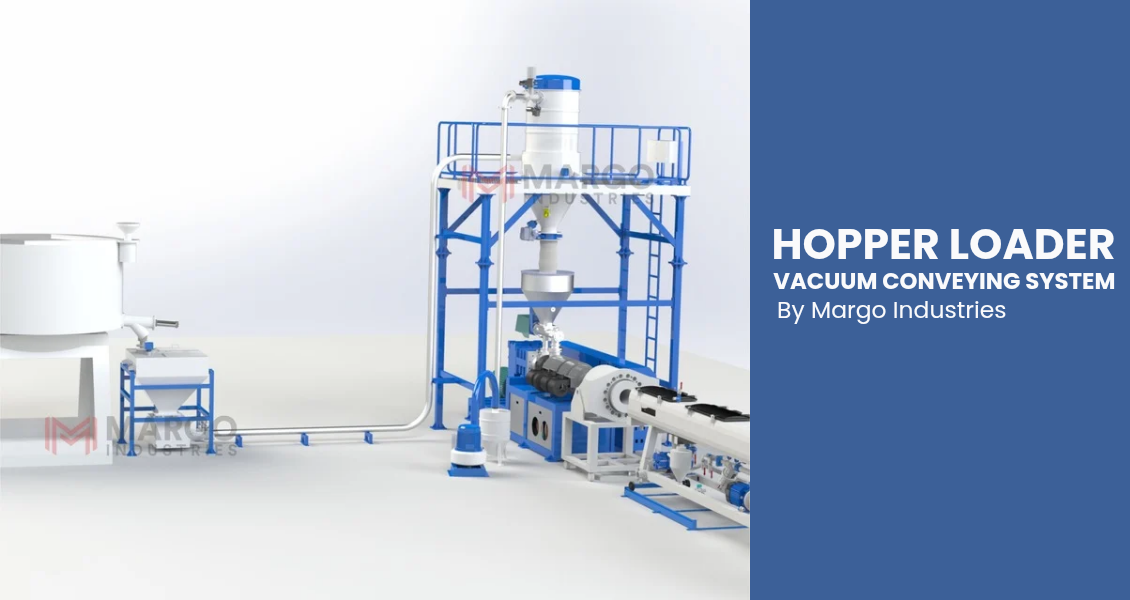

Hopper Loader Vacuum Conveying System – Precision Material Transfer for Modern Industry

In today’s fast-paced industrial landscape, efficiency, hygiene, and automation are more critical than ever. One key technology that revolutionizes material handling across multiple sectors is the Hopper Loader Vacuum Conveying System. Designed to deliver powdery, granular, and pelletized raw materials with precision and safety, these systems ensure smooth, contamination-free transfer that boosts productivity and operational reliability.

This comprehensive guide explores every facet of Hopper Loader Vacuum Conveying Systems — from their core technology and applications to advanced features, industry benefits, and why Margo Industries stands as a leading innovator in this field.

What is a Hopper Loader Vacuum Conveying System?

Definition and Functionality

A hopper loader vacuum conveying system is a specialized automated equipment that uses vacuum suction to transfer bulk materials such as powders, granules, and pellets from one location to another — typically from storage silos or bags to processing machines like mixers, extruders, or reactors. It replaces manual loading, enhancing process efficiency while maintaining material integrity.

How It Fits Into Industrial Automation

Modern industries demand automated solutions to reduce manual labor, minimize contamination, and maintain clean environments. Hopper loaders are vital components of such automated material handling setups, seamlessly integrating with PLCs, SCADA systems, and other control platforms to provide real-time monitoring and smart operation.

Suitable Material Types

- Fine powders (e.g., flour, sugar, pharmaceutical powders)

- Granules and pellets (e.g., plastic resins, chemical granules)

- Sensitive and hygienic materials requiring GMP-compliant handling

Why Are Hopper Loader Systems Essential in Today’s Industry?

Increased Operational Efficiency

Manual loading is labor-intensive and prone to errors like overfilling, spills, and contamination. Hopper loaders automate these processes, reducing cycle times and allowing continuous or batch operation tailored to production demands.

Enhanced Safety and Hygiene

By enclosing the material handling process, these systems protect workers from dust exposure, allergens, and hazardous substances. Food, pharma, and chemical industries particularly benefit from reduced contamination risk and compliance with stringent hygiene standards.

Environmental and Regulatory Compliance

Enclosed vacuum conveying systems minimize dust emissions and energy consumption, helping factories meet occupational safety and environmental standards.

Core Technology and Features

1. High-Efficiency Vacuum Pump

At the heart of the system lies a powerful vacuum pump designed for robust and continuous operation. It creates the necessary negative pressure to suck material efficiently while maintaining airflow balance to prevent blockages or damage to materials.

2. Intelligent Control Systems

Modern hopper loaders feature automated material level sensors and start/stop functions to prevent overloading. Integration with PLC and SCADA allows centralized process control, remote diagnostics, and predictive maintenance alerts.

3. Modular and Scalable Architecture

These systems are built with modular components, enabling easy scalability as plant capacities grow. Users can expand hopper sizes or add multiple loaders connected to a central vacuum source for complex production lines.

4. Hygiene-Focused Construction

Food-grade and pharma-grade variants are constructed using SS304 or SS316 stainless steel with electropolished surfaces to prevent bacterial growth and facilitate easy cleaning. Compatibility with CIP (Clean-In-Place) and WIP (Wash-In-Place) systems ensures minimal downtime.

Detailed Working Principle of Hopper Loader Systems

Vacuum Generation

The vacuum pump draws air from the conveying line, creating negative pressure inside the hopper loader. This pressure differential acts as the suction force to pick up materials.

Material Suction and Conveyance

Material is drawn into the system through a lance or wand inserted into the source container. The vacuum pulls material through sealed pipelines, ensuring no spillage or exposure to the environment.

Separation and Discharge

Conveyed material enters a cyclone separator or filter housing that separates it from the air stream. Clean air is exhausted while material collects in the receiving hopper. Automatic filter cleaning systems maintain airflow and prevent downtime.

Industrial Applications of Hopper Loader Vacuum Conveying Systems

Plastics and Polymer Industry

Used extensively for transferring resin pellets to extruders, these systems prevent bridging and dust formation, ensuring uninterrupted production.

Pharmaceutical Manufacturing

Critical for handling active pharmaceutical ingredients (APIs) and excipients in sterile environments, preventing cross-contamination and ensuring product purity.

Food and Beverage Processing

Ideal for transferring flour, sugar, spices, and other ingredients, these systems meet FDA and GMP regulations, maintaining high food safety standards.

Chemical Industry

Designed to safely convey corrosive, flammable, or explosive materials with options for ATEX certification and anti-static construction.

Technical Specifications Overview

| Parameter | Details |

| Conveying Capacity | 100 – 2000 kg/hour |

| Maximum Conveying Distance | Up to 30 meters |

| Vacuum Level | -400 to -900 mbar |

| Construction Material | SS304 / SS316 Stainless Steel |

| Surface Finish | Electropolished or Matte |

| Filter Media | HEPA, PTFE, or Customizable |

| Control Integration | PLC, HMI, SCADA, IoT-enabled |

Benefits of Choosing Margo’s Hopper Loader System

1. Superior Operational Efficiency

Automated controls reduce downtime and improve cycle times, allowing precise batch or continuous material feeding.

2. Clean and Safe Material Handling

The enclosed design prevents dust emissions, safeguarding workers and the production environment.

3. Minimized Material Loss and Waste

Precision suction and dosing ensure uniform feed rates and reduce spillage.

4. Easy Maintenance

Tool-free access to contact parts enables quick cleaning and servicing, supported by Margo’s extensive spare parts availability.

Why Partner With Margo Industries?

Decades of Industry Expertise

Margo Industries brings over 50 years of engineering excellence, delivering proven systems across plastic, pharma, food, and chemical sectors.

Customized Solutions

We design tailored hopper loaders based on your specific material properties and process requirements, ensuring maximum efficiency.

In-House Manufacturing & R&D

Our fully integrated manufacturing and testing facilities guarantee quality control and rapid project delivery.

End-to-End Support

From installation and commissioning to training and 24/7 after-sales service, Margo Industries is committed to your success.

Automation and Integration

SCADA & IoT Compatibility

Our systems support real-time monitoring, data logging, remote alerts, and analytics for predictive maintenance and process optimization.

Seamless Plant Integration

Easy synchronization with mixers, extruders, silos, and batching systems enhances overall plant automation.

Customization and Special Features

Hopper Size Variants

From small lab-scale units to large industrial hoppers, available in standard and customized volumes.

Multi-Loader Systems

Centralized vacuum systems can serve multiple loaders with staggered operation for complex workflows.

Special Environments

ATEX-certified models for explosive atmospheres, cleanroom-compliant designs for pharma and food sectors.

Certifications and Compliance

- CE Marking

- FDA-Grade Materials

- GMP Manufacturing Standards

- ATEX Certification (optional)

- Occupational Safety and Environmental Regulations

Real-World Success Stories

Case Study: Plastic Compounder

Challenge : Frequent downtime due to material bridging and inconsistent feeding.

Solution : Installation of Margo’s hopper loader with automated controls and enhanced vacuum pumps.

Outcome : 30% increase in uptime, reduced material waste, and improved product quality.

Client Testimonials

“Margo’s hopper loader has revolutionized our production line — reliable and efficient.” – Senior Engineer, Leading Polymer Manufacturer

Frequently Asked Questions (FAQs)

Q: How often should maintenance be performed?

A: Generally, every six months, depending on material type and usage intensity.

Q: Can the system handle multiple load points?

A: Yes, multi-loader configurations allow for simultaneous conveying to various locations.

Q: How is the filter cleaned?

A: Automatic pulse-jet or reverse air cleaning systems maintain filter efficiency with minimal manual input.

Q: Is the system safe for explosive dust environments?

A: Yes, we offer ATEX-certified models designed for hazardous zones.

Q: What is the typical installation timeline?

A: Installation and commissioning usually take 2–4 weeks depending on complexity.