The Importance of Accurate Liquid Dosing in Modern Industry

In today’s industrial landscape, precision in liquid dosing is no longer optional—it is essential. From plastics and chemicals to pharmaceuticals and food processing, industries depend on accurate liquid dosing and weighing systems to ensure consistent product quality, meet regulatory standards, and minimize material waste. Even small deviations in liquid measurement can lead to product rejection, costly rework, or safety hazards, making precision dosing a critical part of any modern production process.

Traditional vs. Automated Liquid Dosing Systems

Traditionally, liquid dosing has been handled manually or through semi-automated setups, which often rely heavily on operator skill and can be prone to error. These systems are not only time-consuming but also lack the consistency required for today’s high-performance production environments.

By contrast, automated liquid dosing systems offer unmatched accuracy, repeatability, and control. Leveraging technologies like PLCs, load cells, and SCADA integration, these systems allow manufacturers to automate batch processing, reduce labor costs, and maintain high production standards.

Why Industries Are Moving Toward Automation

As industries face growing pressure to improve efficiency, maintain quality, and scale operations, the move toward automation has become a strategic priority. Automated dosing systems reduce human error, speed up production cycles, and provide data for process optimization and compliance reporting.

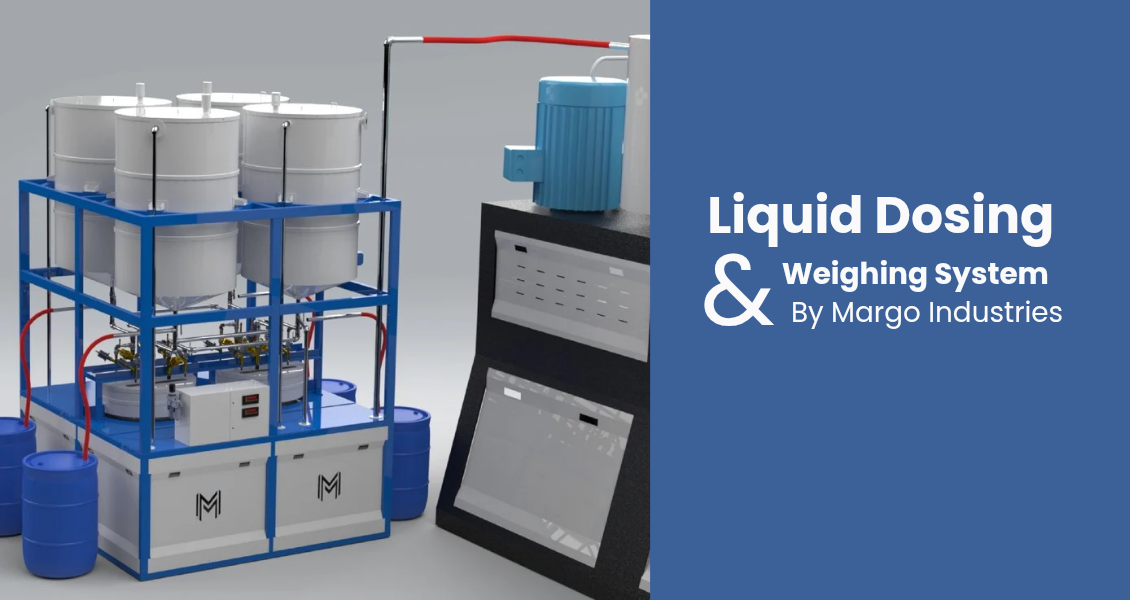

Margo Industries: A Trusted Solution Provider

Margo Industries, with over 50 years of engineering excellence, has established itself as a reliable partner in delivering high-performance liquid dosing and weighing systems. Known for precision, durability, and customization, Margo’s systems are trusted by manufacturers across diverse industries for their reliability and long-term performance.

What is a Liquid Dosing and Weighing System?

Definition and Working Principle

A liquid dosing and weighing system is an industrial automation solution designed to deliver precise quantities of liquids into a process stream or batch operation. These systems are used to ensure accurate formulation, improve production efficiency, and reduce material waste. The working principle involves drawing a specific volume or weight of liquid from a storage source and dosing it into the target container or process, either continuously or in batches, based on predefined parameters.

The system measures the quantity of liquid using load cells or flow meters, with the dosing process controlled via PLCs (Programmable Logic Controllers) or SCADA systems for real-time monitoring and adjustment.

Core Components of a Liquid Dosing System

A typical liquid dosing and weighing system includes:

- Storage Tank – Holds the liquid before dosing

- Dosing Pump – Transfers liquid from the tank to the processing point

- Load Cell or Flow Meter – Measures weight or volume accurately

- Control Panel/PLC – Automates and controls the dosing cycle

- Valves and Piping – Direct and regulate liquid flow

- Level Sensors and Safety Alarms – Monitor system status and prevent overflows or errors

Types of Dosing: Volumetric vs. Gravimetric

- Volumetric Dosing : Measures liquid based on volume (liters or milliliters), typically using flow meters. It’s faster but less accurate if liquid density varies.

- Gravimetric Dosing : Measures based on weight (kilograms or grams) using load cells. It offers superior precision, especially for critical formulations.

Integration with PLC and SCADA Systems

Modern dosing systems integrate seamlessly with PLC and SCADA platforms, enabling full automation, data logging, recipe management, and real-time process control. This integration allows industries to maintain consistent quality, reduce operator dependency, and achieve traceability for audits and compliance.

Liquid Dosing and Weighing Systems: Comprehensive Overview

A liquid dosing system is essential equipment in modern industries, enabling precise measurement and dispensing of liquids in various manufacturing processes. The liquid dosing and weighing system integrates dosing pumps with advanced weighing technologies to achieve high accuracy and consistency in liquid handling. These systems support automated liquid dosing, which reduces human error and improves productivity.

The core of these setups includes industrial liquid dosing equipment such as liquid dosing pumps, load cell based liquid dosing systems, and controllers like PLC liquid dosing systems that automate and control the dosing operations. Depending on the need, these systems can perform gravimetric liquid dosing—which measures the weight of liquid—or volumetric liquid dosing systems—which dose based on volume or flow rate. Advanced options include multi-component liquid dosing systems, ideal for complex recipes in industries like pharmaceuticals, food and beverage, and chemical processing.

Industry leaders seek customizable liquid dosing systems with features like CIP friendly liquid dosing systems for easy cleaning, alarms in liquid dosing systems to detect faults, and seamless integration with SCADA systems for real-time monitoring. The increasing demand for automated liquid dosing solutions for industry arises from the need to ensure high-accuracy liquid weighing and dosing, especially in sensitive sectors like pharmaceuticals and food manufacturing.

When deciding to buy liquid dosing systems, customers often consult liquid dosing system suppliers and manufacturers offering competitive pricing, such as industrial liquid dosing system price options that balance cost with quality. Additionally, services including liquid dosing system installation services, warranty, and liquid dosing system maintenance services are crucial to maximize system uptime and reliability.

Understanding what is a liquid dosing system, how does a liquid dosing and weighing system work, and the benefits of automated liquid dosing helps industries optimize production. Compared to manual dosing, these systems guarantee superior repeatability and reduced waste. There are various types of liquid dosing systems, and knowing the liquid dosing system accuracy importance is vital when selecting liquid dosing equipment. Keeping abreast of the latest trends in liquid dosing technology and familiarizing oneself with liquid dosing system troubleshooting tips ensures smooth operation.

Applications of liquid dosing and weighing systems span multiple sectors, from precise liquid dosing system for pharmaceuticals to liquid dosing system for food and beverage production and liquid dosing system for chemical processing.

For those searching for trusted solutions, Margo Industries liquid dosing system and Margo liquid dosing and weighing solutions offer robust, customizable systems. Prospective buyers can contact Margo Industries for dosing system inquiries or explore their extensive Margo Industries product catalog to find the best fit. Their Margo Industries automation solutions combine innovation with reliability, backed by excellent customer service.

Why Accuracy in Liquid Dosing Matters

Ensuring Consistent Quality in Formulations

In industries where formulations are highly specific—such as chemicals, plastics, pharmaceuticals, and food processing—precision in liquid dosing is critical. Even a small deviation in the quantity of liquid additives, binders, or solvents can compromise the consistency, safety, or performance of the final product. High dosing accuracy ensures that each batch meets stringent quality standards, reduces the risk of product rejection, and helps maintain brand reliability in competitive markets.

Precision Dosing as a Cost-Control Strategy

Accurate liquid dosing directly contributes to cost savings across the production line. Overdosing results in excessive consumption of raw materials, while underdosing may require reprocessing or lead to defective batches. Both outcomes increase operating costs. By maintaining exact dosing parameters—especially in high-volume environments—manufacturers can control input costs, reduce waste, and improve profitability without compromising on quality.

Environmental Impact: Reducing Spillage and Waste

Modern industries are under increasing pressure to improve sustainability and reduce environmental footprints. Automated and accurate liquid dosing systems help minimize liquid waste, spillage, and manual handling errors that can lead to pollution or contamination. By optimizing material usage and eliminating excess, businesses not only comply with environmental regulations but also demonstrate corporate responsibility.

Case Example: The Impact of a 2% Error

Consider a high-throughput plastic compounding plant using 10,000 liters of liquid additive per week. A consistent 2% overdose amounts to 200 liters of unnecessary consumption—resulting in substantial financial loss over time. On the flip side, a 2% underdose could lead to product defects, non-compliance, or increased customer complaints. Over a year, this minor dosing inaccuracy could translate to thousands of liters wasted and lakhs of rupees in lost value.

Types of Liquid Dosing Systems

Selecting the right type of liquid dosing system is essential for optimizing accuracy, efficiency, and cost-effectiveness in manufacturing processes. Different dosing methods are suited to different applications, depending on the required precision, production volume, and the nature of the liquid being handled.

Volumetric Dosing Systems

Flow-Rate and Time-Controlled Operation

Volumetric dosing systems measure liquid based on volume, using flow meters, timing mechanisms, or displacement pumps. These systems dose a set volume of liquid over a specified time, assuming that the fluid’s flow rate remains stable.

Best for Non-Critical Operations

While volumetric systems are simple and cost-effective, they can be sensitive to changes in viscosity, temperature, and pressure, which affect flow rate. As a result, they are most suitable for non-critical or stable applications where minor deviations are acceptable—for example, in general water dosing, basic cleaning solutions, or internal recirculation processes.

Gravimetric Dosing Systems

Weight-Based Precision

Gravimetric dosing systems measure liquid by weight using load cells or electronic scales. These systems offer a closed-loop feedback mechanism, adjusting the flow in real-time to ensure that the exact target weight is reached.

Ideal for High-Accuracy Applications

Gravimetric systems are widely used in industries where formulation accuracy is crucial, such as chemical compounding, pharmaceuticals, and specialty polymers. They offer excellent repeatability and can accommodate variable liquid densities, making them more reliable than volumetric systems for critical operations.

Batch vs. Continuous Dosing Systems

When to Use Each

- Batch Dosing delivers a precise, pre-defined quantity of liquid for each production cycle. It is ideal for batch manufacturing environments where exact formulation per cycle is necessary.

- Continuous Dosing supplies a consistent liquid feed over time and is typically used in continuous production lines, such as extrusion, coating, or blending processes. While slightly less accurate than batch dosing, it is highly efficient for high-throughput operations.

Multi-Component Liquid Dosing Systems

In advanced manufacturing environments, multi-component dosing systems are used to handle and combine several liquids simultaneously. These systems are essential in:

- Masterbatch production – dosing colorants, plasticizers, and stabilizers

- Adhesives and sealants – precise blending of resins and hardeners

- Chemical processing – combining multiple reactants in exact ratios

Multi-component systems require intelligent control via PLCs or SCADA for synchronizing flows, ensuring consistency, and preventing cross-contamination.

Core Features of Margo Industries’ Liquid Dosing System

Margo Industries is renowned for delivering advanced liquid dosing and weighing systems that combine precision, durability, and automation. Designed to meet the diverse needs of industries such as plastics, chemicals, pharmaceuticals, and food processing, Margo’s dosing systems incorporate several key features that set them apart in terms of performance and reliability.

PLC and SCADA-Enabled Automated Control

At the heart of Margo’s liquid dosing systems lies an intelligent control architecture powered by Programmable Logic Controllers (PLC) and SCADA (Supervisory Control and Data Acquisition) software. This integration enables real-time monitoring, remote control, and automated adjustments to dosing parameters, ensuring consistent accuracy and minimizing human intervention. Operators can easily program recipes, monitor system status, and generate detailed reports for quality assurance and compliance.

Robust Stainless Steel Construction

Understanding the harsh environments in which dosing systems operate, Margo Industries utilizes high-grade stainless steel for all wetted parts and structural components. This choice ensures excellent resistance to corrosion, chemical attack, and wear—extending equipment life and reducing maintenance costs. The hygienic design also supports use in pharmaceutical and food-grade applications.

Clean-in-Place (CIP) Friendly Design

Maintenance and hygiene are critical, especially in industries handling reactive or sensitive liquids. Margo’s dosing systems are engineered with Clean-in-Place (CIP) capabilities, allowing automated cleaning cycles without disassembly. This feature significantly reduces downtime, labor costs, and contamination risks, improving overall plant efficiency.

Online Weight Monitoring with High-Precision Load Cells

For precise dosing, Margo systems employ high-accuracy load cells that continuously measure the weight of the liquid being dispensed. This online weight monitoring provides immediate feedback to the control system, enabling closed-loop corrections to maintain exact dosing volumes. The result is consistent product quality, reduced waste, and minimized errors.

Alarms for Over-Dosing and Under-Dosing

To safeguard the production process, Margo’s systems include built-in alarm mechanisms that alert operators in case of dosing deviations—whether it’s over-dosing or under-dosing. These alarms help prevent batch failures, equipment damage, or safety hazards, ensuring operational reliability.

Advanced Recipe Management for Batch Dosing

Margo’s liquid dosing systems support sophisticated recipe management, allowing users to store, select, and execute multiple dosing recipes easily. This flexibility is especially valuable for batch production environments, enabling quick changeovers and consistent adherence to formulation standards.

Applications Across Industries

Liquid dosing and weighing systems are versatile and widely used across multiple industries to enhance accuracy, efficiency, and product quality. Below are some key sectors where these systems play a crucial role:

Industry-Specific Applications

- Plastics and Compounding

Precise dosing of lubricants, colorants, stabilizers, and plasticizers to ensure consistent polymer quality and performance. - Chemical Processing

Accurate feeding of acids, bases, and catalysts for neutralization, reaction control, and formulation consistency. - Pharmaceuticals

Precision dosing of active pharmaceutical ingredients (APIs) and excipients critical for drug efficacy and safety. - Food and Beverage

Controlled addition of flavors, colorants, preservatives, and other additives to maintain taste, appearance, and shelf life. - Paints and Coatings

Metering resins, solvents, and additives to achieve desired color, texture, and protective properties.

These applications highlight how liquid dosing systems improve manufacturing accuracy, reduce waste, and ensure compliance with stringent industry standards. Margo Industries’ customized solutions cater to the specific needs of these sectors, delivering reliable and efficient dosing systems that support high-quality production.

Benefits of Using Automated Liquid Dosing Systems

Incorporating automated liquid dosing systems into industrial processes offers a range of benefits that drive operational excellence, cost savings, and product quality. Here are the key advantages:

Reduced Human Error

Manual dosing methods are prone to inconsistencies and mistakes due to fatigue, oversight, or lack of precision. Automated systems minimize these risks by precisely controlling dosing parameters, ensuring accurate and reliable liquid measurement every time. This reduction in human error improves product quality and reduces costly rework or scrap.

Consistency and Repeatability

Automated liquid dosing ensures that each batch receives the exact same amount of liquid additives or components, promoting uniformity across production cycles. This repeatability is essential in industries such as pharmaceuticals and chemicals where even minor variations can impact product performance and regulatory compliance.

Enhanced Plant Safety

By automating the dosing process, exposure to hazardous chemicals or liquids is significantly reduced for plant operators. Safety interlocks, alarms for over- or under-dosing, and controlled environments decrease the likelihood of spills, accidents, or unsafe conditions on the plant floor.

Traceability Through Data Logging

Modern dosing systems integrated with PLC and SCADA enable comprehensive data logging of dosing parameters, batch information, and process anomalies. This traceability supports quality audits, regulatory compliance, and continuous process improvement by providing detailed records of each production cycle.

Faster Batch Production Cycles

Automation speeds up the dosing process by eliminating manual preparation and adjustment times. Precise, repeatable dosing reduces downtime between batches and increases overall throughput, helping manufacturers meet tight production schedules and demand fluctuations efficiently.

Labor and Time Savings

Automated dosing systems reduce dependency on skilled operators for repetitive tasks, freeing up human resources for higher-value activities. The reduced need for manual intervention also cuts down operational labor costs and minimizes human resource challenges during peak production periods.

By leveraging these benefits, industries can enhance product quality, improve operational efficiency, and maintain a competitive edge in increasingly demanding markets. Margo Industries’ automated liquid dosing solutions are designed to deliver these advantages seamlessly.

How to Select the Right Dosing System for Your Plant

Choosing the ideal liquid dosing system is crucial for optimizing production efficiency, ensuring product quality, and minimizing costs. Several key factors should be carefully considered to select the best system tailored to your plant’s unique requirements.

Key Factors to Consider

Flow Rate and Dosing Accuracy

Determine the required flow rate and dosing precision for your application. High-volume operations may need systems capable of continuous dosing, while batch processes demand precise quantity control. Accuracy requirements vary by industry—pharmaceuticals often need higher precision than general chemical dosing.

Type of Liquid

Consider the physical and chemical properties of the liquid:

- Viscosity : Thick or viscous liquids may require specialized pumps or dosing methods.

- Corrosiveness : Corrosive liquids demand robust materials such as stainless steel to ensure system longevity.

- Temperature : Liquids at extreme temperatures may need heated or insulated components.

Level of Automation

Decide whether a manual, semi-automated, or fully automated (PLC-controlled) system suits your operation. Automated systems provide better accuracy, data logging, and integration with existing plant control networks, but manual systems may suffice for simple or low-volume tasks.

Ease of Maintenance

Opt for dosing systems designed for easy cleaning and maintenance. Features like Clean-in-Place (CIP) capabilities and modular components reduce downtime and maintenance labor.

Integration with Plant Equipment

Ensure the dosing system can seamlessly interface with existing mixers, feeders, extruders, or process lines. Compatibility with control systems like SCADA allows for synchronized operations and enhanced process control.

Dosing System Selection Checklist

- Define your required dosing accuracy and flow rate

- Analyze liquid characteristics (viscosity, corrosiveness, temperature)

- Choose the appropriate automation level (manual, semi-auto, fully automated)

- Verify the system’s maintenance and cleaning features

- Confirm compatibility and integration with existing plant equipment and control systems

By following this checklist, manufacturers can make informed decisions that optimize production efficiency and product quality. Margo Industries offers customizable liquid dosing solutions to meet diverse operational needs and scale as your plant grows.

Maintenance and Best Practices

Routine Calibration of Load Cells

Accurate dosing depends heavily on the precision of load cells. Regular calibration is essential to maintain measurement accuracy and system reliability. It’s recommended to perform calibration checks at scheduled intervals or after maintenance to ensure the load cells provide consistent and trustworthy weight readings.

Cleaning Protocol

Maintaining cleanliness in the dosing system is critical, especially when handling sticky, viscous, or volatile liquids. Implementing a strict cleaning protocol, including Clean-in-Place (CIP) procedures if available, helps prevent contamination, buildup, and corrosion. Thorough cleaning reduces downtime, improves system longevity, and ensures consistent dosing quality.

Software Backup and Alarm System Checks

Periodic backups of dosing system software and recipe databases safeguard against data loss due to system failures or updates. Additionally, regular testing of alarm systems—such as over-dosing or under-dosing alerts—ensures that potential issues are detected early, minimizing risks to product quality and plant safety.

Adhering to these maintenance best practices maximizes the performance and lifespan of liquid dosing systems, helping manufacturers maintain operational excellence and regulatory compliance.

Trends & Innovations in Liquid Dosing

The liquid dosing industry is rapidly evolving with the integration of advanced technologies aimed at improving precision, efficiency, and connectivity.

IoT and Cloud-Based Monitoring

Modern dosing systems increasingly leverage Internet of Things (IoT) technology to enable real-time data collection and remote monitoring via cloud platforms. This connectivity allows plant managers to track dosing performance, detect anomalies early, and make data-driven decisions from anywhere, enhancing operational transparency and responsiveness.

AI-Assisted Dosing Predictions

Artificial Intelligence (AI) is transforming liquid dosing by providing predictive analytics and adaptive control. AI algorithms analyze historical dosing data and process variables to forecast optimal dosing parameters, reduce errors, and adjust operations dynamically—leading to higher accuracy and reduced material waste.

Integration with Industry 4.0 and MES

Liquid dosing systems are becoming integral components of Industry 4.0 frameworks, seamlessly interfacing with Manufacturing Execution Systems (MES) and other automation tools. This integration streamlines production workflows, improves traceability, and supports flexible manufacturing processes—empowering manufacturers to meet evolving market demands efficiently.

Staying ahead with these innovations ensures that dosing operations remain precise, agile, and future-ready.

Why Choose Margo Industries?

With over 50 years of experience in the industry, Margo Industries has built a strong reputation as a reliable provider of high-quality liquid dosing and weighing systems. This extensive expertise enables Margo to understand the unique challenges faced by various sectors and deliver solutions that are both innovative and dependable.

One of the key strengths of Margo Industries is its customization capability. Each dosing system is designed and engineered to meet the specific requirements of the client, whether it involves handling challenging liquids, complex automation needs, or integration with existing plant infrastructure. This tailored approach ensures maximum efficiency and precision in every application.

Margo Industries offers comprehensive local and international installation support, ensuring smooth deployment and startup regardless of your location. Their team of experts provides hands-on assistance and training to guarantee seamless integration into your production line.

Beyond installation, Margo provides robust after-sales service including maintenance, troubleshooting, and technical support. This commitment to customer satisfaction ensures long-term reliability and optimal system performance.

Choosing Margo Industries means partnering with a trusted expert dedicated to delivering cutting-edge technology, tailored solutions, and exceptional support for your liquid dosing needs.