Bulk material handling is an essential process across multiple industries including chemical manufacturing, pharmaceuticals, food processing, construction, and more. Efficiently handling and processing raw materials such as powders, granules, pellets, and liquids at large scales is critical to maintaining smooth operations, ensuring product quality, and keeping costs under control.

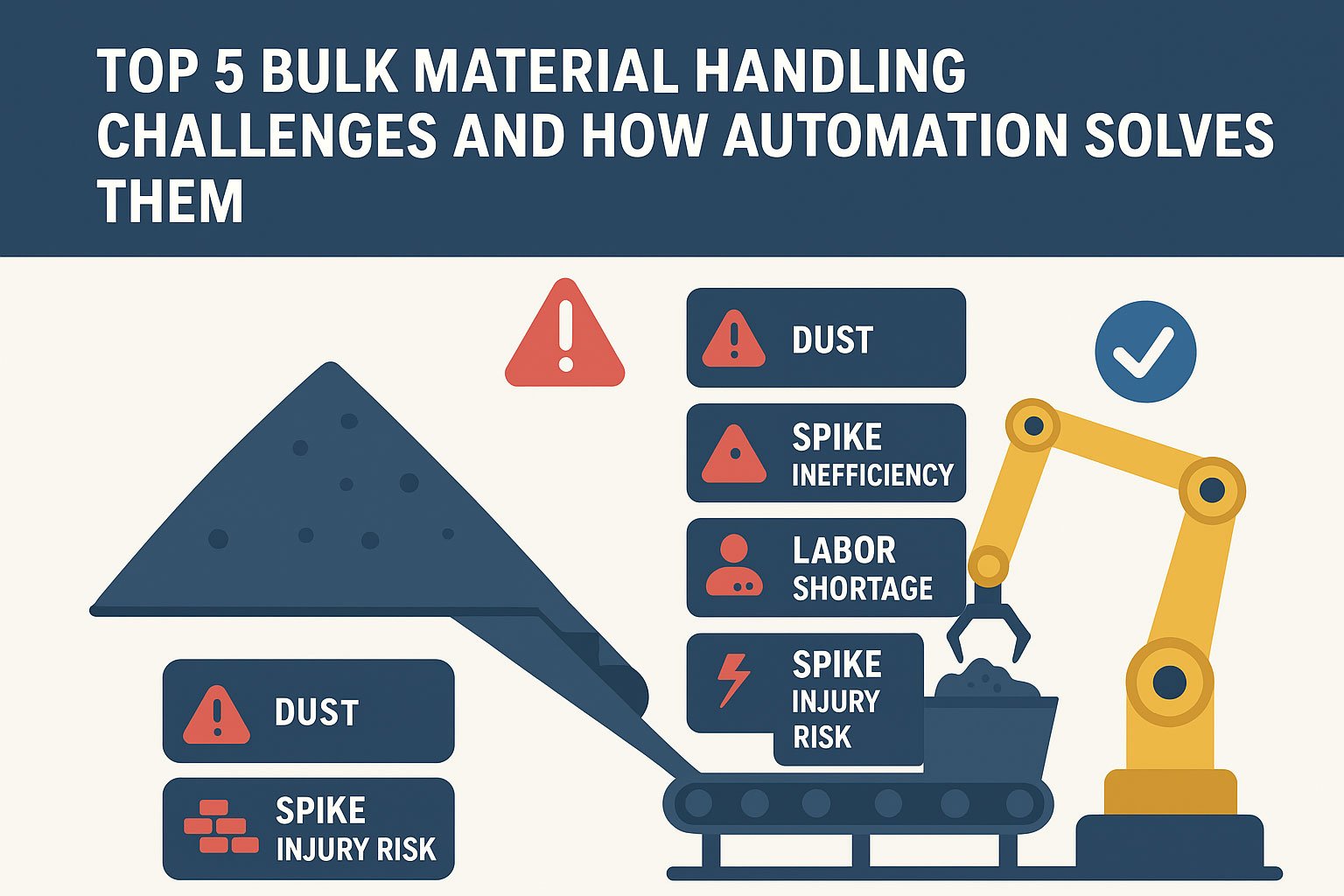

Despite its importance, bulk material handling is fraught with challenges — from dust and spillage to inaccurate weighing and safety hazards. Many companies still rely on manual labor or outdated equipment, which often leads to operational inefficiencies, increased downtime, safety incidents, and material losses.

In this detailed blog, we will uncover the Top 5 Challenges in Bulk Material Handling and explore how automation, especially the innovative solutions offered by Margo Industries, can solve these problems effectively. This will help businesses increase productivity, improve safety, and reduce operational costs.

Challenge 1: Dust Generation and Material Spillage

Understanding the Problem

One of the most common challenges in bulk material handling is controlling dust emissions and material spillage during loading, unloading, and transfer. Dust is a health hazard for workers, causing respiratory issues and allergic reactions. It also contaminates the environment, leading to regulatory fines and increased cleanup costs.

Material spillage results in wasted raw materials, creating unnecessary operational expenses. Additionally, spillage can create safety hazards such as slippery floors or equipment blockages.

The Impact of Dust and Spillage

- Health risks: Dust particles inhaled by workers can cause long-term lung diseases, allergies, and acute respiratory problems.

- Environmental concerns: Dust emissions pollute the surrounding air and contribute to workplace contamination.

- Operational losses: Spilled material means direct financial loss and added cleaning downtime.

- Regulatory non-compliance: Many industries face strict regulations related to dust control and waste management. Failing to comply can result in penalties and production shutdowns.

Automation Solutions by Margo Industries

Margo Industries addresses this challenge head-on with innovative automation solutions designed to prevent dust emissions and eliminate spillage:

- Jumbo Bag Debagging Station

Designed to handle large bulk bags safely, this system includes an airtight enclosure with dust extraction units, enabling the unloading of raw materials without dust escaping. This station optimizes debagging processes while ensuring worker safety and environmental protection.

Explore the Jumbo Bag Debagging Station - Bag Dumping Station for Calcium

Tailored specifically for calcium handling, this bag dumping station integrates dust control and material containment features to prevent loss during transfer. The design minimizes manual intervention, enhancing safety and efficiency.

Learn more about Bag Dumping Station for Calcium - Vacuum Conveying System

Vacuum conveyors transport materials in a sealed environment using controlled vacuum pressure. This system virtually eliminates dust escape and spillage by keeping the material enclosed throughout the transfer process.

See Vacuum Conveying System

Benefits of Automation for Dust and Spillage Control

- Nearly zero dust emission, protecting workers and meeting environmental regulations.

- Material loss reduction, resulting in significant cost savings.

- Enhanced workplace cleanliness and safety.

- Improved operational efficiency through minimized downtime.

Challenge 2: Ensuring Consistent Material Flow and Avoiding Blockages

Why Material Flow Consistency Matters

Bulk materials often exhibit diverse physical properties — some powders may be free-flowing, while others are sticky or prone to clumping. These variations can cause irregular flow, leading to blockages in conveyors, feeders, or hoppers.

Blockages not only halt production but can also cause damage to equipment or require manual clearing, which is time-consuming and hazardous.

Common Causes of Flow Problems

- Variations in particle size and moisture content

- Electrostatic charges causing materials to stick

- Design flaws in hoppers or chutes

- Insufficient mechanical agitation or flow aids

Consequences of Flow Interruptions

- Production stoppages and missed deadlines

- Increased labor costs for manual clearing

- Equipment wear and tear due to sudden surges or overloading

- Lower product quality due to inconsistent feeding

Automated Solutions from Margo Industries

Margo Industries offers advanced mechanical and pneumatic conveying solutions designed to maintain smooth, consistent flow of bulk materials:

- Screw Conveyor

This mechanical conveyor uses a rotating helical screw to move materials through a tubular casing. It’s highly effective in moving powders and granules while preventing clogging. Customizable screw conveyors ensure proper pitch, diameter, and speed to suit various materials.

Check out the Screw Conveyor - Pressure Conveying System to Feed Storage Silos

Using positive pressure to push materials through pipelines, these systems ensure steady material flow over long distances. They are designed to handle different materials without blockages and integrate seamlessly with storage silos.

Learn more about Pressure Conveying System

Benefits of Automated Flow Control

- Continuous, reliable material movement prevents costly production downtime.

- Reduced manual labor and risk associated with clearing blockages.

- Extended equipment life due to smoother operation.

- Higher consistency in product formulation and quality.

Challenge 3: Achieving Accurate Weighing, Dosing, and Batching

The Importance of Precision in Bulk Handling

Accurate weighing and dosing of raw materials are vital in industries like pharmaceuticals, chemicals, and food processing. Slight variations in batch quantities can compromise product quality, safety, and regulatory compliance.

Manual weighing is prone to errors due to human fatigue, measurement inaccuracies, or timing mismatches during batching.

Problems with Manual Batching

- Over or under-dosing leading to product inconsistencies

- Increased wastage of expensive raw materials

- Slower production cycles due to manual verification steps

- Higher risk of non-compliance with quality standards

How Margo Industries Automates Accurate Weighing

Margo Industries offers sophisticated automated weighing and dosing systems that eliminate human errors:

- Automatic Batch Weighing System

This system provides highly precise weight measurements and controlled batch feeding for powders and granules, optimizing formulation accuracy and repeatability. It can be programmed for complex recipes, ensuring consistent output every time.

Discover the Automatic Batch Weighing System - Liquid Dosing and Weighing System

Combining precise liquid measurement and dosing, this solution is essential for processes requiring accurate addition of liquid ingredients alongside powders. It features automated controls for minimal manual intervention.

See Liquid Dosing and Weighing System - Powder and Liquid Weighing Dosing System

This integrated system handles both powders and liquids in batch processes, ensuring exact formulations and simplifying recipe management. Ideal for complex production lines needing multi-material handling.

Explore Powder and Liquid Weighing Dosing System

Benefits of Automated Weighing and Batching

- Consistent product quality through exact ingredient control.

- Reduction in raw material waste and cost savings.

- Faster batch preparation, increasing throughput.

- Easier compliance with strict regulatory standards.

Challenge 4: Worker Safety and Ergonomic Concerns

Risks of Manual Bulk Material Handling

Manual handling of heavy bags, frequent lifting, and exposure to dust or hazardous materials can lead to serious health and safety issues, including:

- Musculoskeletal injuries from repetitive lifting and awkward postures

- Exposure to airborne dust causing respiratory illnesses

- Slips, trips, and falls from spillage or cluttered workplaces

Economic and Legal Impacts of Poor Safety

- High workers’ compensation claims and insurance premiums

- Increased absenteeism and lower employee morale

- Legal consequences due to non-compliance with occupational health and safety laws

Automation Solutions Enhancing Safety by Margo Industries

Margo Industries focuses heavily on automation that removes manual handling and improves ergonomic conditions:

- Fully Automatic Compounding Plant with PLC SCADA System

This plant automates material handling from raw material feeding to mixing and batching. PLC SCADA provides complete process control and monitoring, reducing human intervention in potentially hazardous environments.

Learn about Fully Automatic Compounding Plant - Hopper Loader Vacuum Conveying System

This system automates the loading of materials into hoppers using vacuum transfer, eliminating the need for manual lifting and reducing dust exposure.

Check Hopper Loader Vacuum Conveying System - Automatic Mixer Feeding System

Automatically feeding mixers with raw materials cuts down manual labor, decreasing ergonomic strain and exposure risks.

See Automatic Mixer Feeding System

Safety Benefits of Automation

- Minimized workplace injuries and health risks.

- Improved morale and productivity among workers.

- Easier compliance with health and safety regulations.

- Reduced downtime caused by accidents.

Challenge 5: System Integration and Real-Time Process Monitoring

The Need for Seamless Integration

Modern bulk material handling is part of larger production ecosystems. Integrating new handling equipment with existing systems is often challenging but critical to avoid process bottlenecks.

Without real-time data and monitoring, detecting equipment faults, material shortages, or process deviations becomes difficult, leading to inefficient operations and unplanned downtime.

Problems from Poor Integration

- Fragmented operations causing delays and miscommunication

- Inability to proactively address equipment failures

- Higher maintenance and operational costs

Margo Industries Solutions for Smart Integration

Margo Industries provides modular systems designed for smooth integration and intelligent process control:

- Raw Material and Recipe Silo

Enables automated storage and recipe management with smart sensors to track inventory and control material flow.

Explore Raw Material and Recipe Silo - Automatic Mixer Feeding System

Fully compatible with plant control systems, providing automatic feeding linked with process parameters.

Automatic Mixer Feeding System Details - PLC SCADA-based control systems provide comprehensive real-time monitoring, enabling operators to control processes remotely, detect faults early, and optimize performance.

Fully Automatic Compounding Plant with PLC SCADA System

Benefits of Integrated Automation Systems

- Holistic process visibility and control for better decision-making.

- Reduced downtime through predictive maintenance and alerts.

- Efficient resource planning and inventory management.

- Improved overall plant productivity and cost-effectiveness.

Summary and Call to Action

Bulk material handling is a complex process with multiple challenges that can hinder efficiency, increase costs, and threaten safety. However, automation is the key to transforming these challenges into opportunities.

Margo Industries’ broad portfolio of automated solutions is designed to tackle every major bulk handling challenge—from dust control and flow consistency to accurate weighing and safety improvements—all integrated with modern control systems for real-time monitoring and optimization.

If you want to future-proof your bulk material handling operations, explore Margo Industries’ products below:

- Jumbo Bag Debagging Station

- Bag Dumping Station for Calcium

- Vacuum Conveying System

- Automatic Batch Weighing System

- Liquid Dosing and Weighing System

- Pressure Conveying System to Feed Storage Silos

- Fully Automatic Compounding Plant with PLC SCADA System

- Hopper Loader Vacuum Conveying System

- Automatic Mixer Feeding System

- Powder and Liquid Weighing Dosing System

- Screw Conveyor

- Raw Material and Recipe Silo

Reach out to Margo Industries today to discuss how we can tailor automation solutions to your bulk handling needs and boost your operational efficiency.

FAQs (Frequently Asked Questions)

Q1. Why is automation important in bulk material handling?

Automation enhances accuracy, safety, and efficiency, reducing human error and operational costs.

Q2. Can Margo Industries customize solutions for specific industry needs?

Yes, they specialize in tailor-made solutions adapted to various bulk handling challenges.

Q3. Do these automated systems integrate with existing plant infrastructure?

Absolutely, Margo’s systems are designed for seamless integration with real-time monitoring and control.

Q4. What industries benefit most from these solutions?

Pharmaceuticals, chemicals, food processing, construction materials, and many more.