Top Pneumatic Conveying System Manufacturer – Custom Solutions for Your Industry Worldwide

Introduction

Choosing the right pneumatic conveying system manufacturer is critical for industries worldwide. Pneumatic conveying systems efficiently transport bulk materials such as powders, granules, and pellets through pipelines using air or gas. These systems reduce manual handling, improve productivity, and enhance safety.

For businesses in food, pharmaceuticals, chemicals, plastics, or recycling, selecting the right system and partnering with an experienced manufacturer directly impacts operational efficiency, cost management, and product quality.

Learn more about our Pneumatic Conveying Systems for global industries.

Why Choosing the Right Manufacturer Matters

Partnering with a reliable manufacturer ensures:

- High-quality systems tailored to your specific industry

- Engineering support during installation, commissioning, and maintenance

- Compliance with international quality and safety standards

- Long-term reliability, reducing downtime and operational costs

A top manufacturer will not only supply the system but also provide guidance to optimize material flow, maintain hygiene standards, and reduce product degradation.

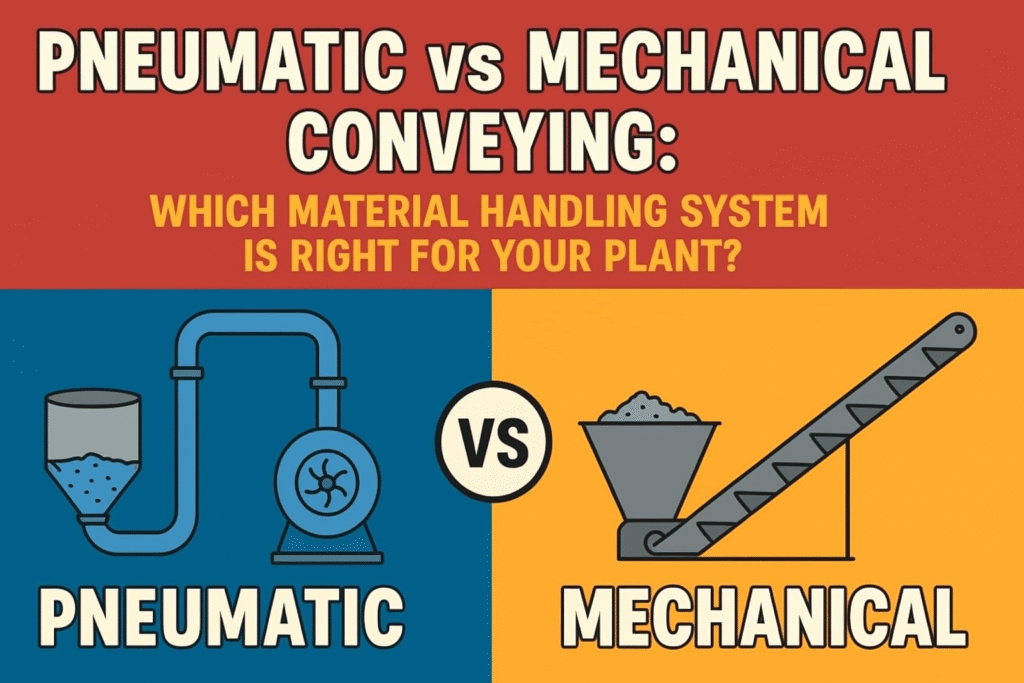

Types of Pneumatic Conveying Systems

Dilute Phase Conveying

- Transports materials suspended in air at high velocity

- Ideal for lightweight and free-flowing materials

- Simple installation and maintenance

Dense Phase Conveying

- Moves materials at a slower, controlled rate with high concentration

- Suitable for fragile, abrasive, or heavy materials

- Reduces material degradation and wear on the system

Choosing the right type depends on material characteristics, production needs, and plant layout.

Key Factors to Evaluate a Manufacturer

Industry Experience & Expertise

- Look for companies with a proven track record in your specific industry

- Verify references, case studies, and global projects delivered

Custom Solutions & Engineering Support

- Systems should be designed to fit your facility layout and throughput requirements

- Ensure technical support is available during installation and commissioning

Certifications & Compliance

- International certifications such as ISO and CE demonstrate quality and safety compliance

- Critical for industries like food, pharmaceuticals, and chemicals

After-Sales Support & Maintenance

- Availability of spare parts and maintenance programs

- Operator training for safe and efficient use

- Remote support for international clients

Discover our custom pneumatic solutions for global operations.

Advantages of Pneumatic Conveying Systems

- Reduces manual labor and material handling

- Minimizes contamination and dust emissions

- Gentle handling preserves product integrity

- Compact design saves floor space

- Energy-efficient modern systems reduce operational costs

- Easy scaling or modification for changing production needs

These advantages make pneumatic systems essential for modern industries seeking efficiency, safety, and reliability.

Applications Across Industries

Food & Beverage

- Hygienic design for powders, granules, and ingredients

- Dust-free handling for product safety

- Dense phase for gentle handling of fragile materials

Pharmaceutical

- Compliance with GMP and international safety standards

- Precise, contamination-free transfer of powders and active ingredients

- Modular designs for various facility layouts

Chemicals & Plastics

- Robust construction for heavy or abrasive materials

- Dense or lean phase systems based on throughput

- Automation and remote monitoring options

Recycling & Waste Management

- Efficient material transport with minimal manual intervention

- Safe handling of potentially hazardous or dusty materials

Why Choose Margo Industries

Margo Industries is a global leader in pneumatic conveying solutions. Key benefits include:

- Extensive experience across multiple industries worldwide

- Custom-engineered systems for specific operational requirements

- Advanced technology ensuring energy efficiency, reliability, and high performance

- Certified quality and robust construction for long-term durability

- Comprehensive after-sales support including maintenance, troubleshooting, and upgrades

Whether your facility is local or international, Margo Industries delivers solutions that maximize efficiency, minimize downtime, and maintain the highest safety and hygiene standards.

Common Mistakes Buyers Make

- Choosing the cheapest supplier without checking quality

- Ignoring industry-specific requirements

- Overlooking after-sales support and spare parts availability

- Not considering long-term maintenance and system scalability

Avoiding these mistakes ensures smooth, cost-efficient operations and reliable system performance.

Conclusion

Selecting the right pneumatic conveying system manufacturer determines the success of your material handling operations. By prioritizing experience, customization, certifications, and after-sales support, businesses worldwide can achieve reliable, efficient, and safe material transfer.